Lesson 4

Calibration, National Standards and Traceability

In the same way as all measurement instruments, hygrometers must be calibrated at the time of manufacture and at intervals during their use. Methods of calibration have evolved over time. Typically, a hygrometer is exposed in a step by step process to a series of samples of air of known humidity over the required humidity range. The hygrometer readings are then programmed in. While this process may sound simple, in fact humidity calibration is a much more difficult task to perform than say temperature or pressure calibration. For a better understanding of the challenges facing anyone calibrating (and even using) a hygrometer, read the Good Practice Guide No. 124, The Beginner's Guide to Humidity Measurement, written by Dr Stephanie Bell of the UK's National Physical Laboratory. www.npl.co.uk/publications/guides/comment/beginners-guide-to-humidity-measurement/

Humidity calibration methods until the 1960s/1970s were relatively primitive and carried out by manufacturers of the fairly basic hygrometers then available. They were based on saturated salts and on sulfuric acid solutions of different concentrations. As the needs of industry began to demand measurement methods with greater precision, dynamic humidity generators evolved. In these, a flowing sample of air with a precisely controlled water vapor content is generated. This can be done in a mixed flow generator, which combines a dry reference flow with a flow saturated at known pressure and temperature. This method requires that a calibration quality hygrometer is placed in the line as a verification method as there is no guarantee otherwise that the dry reference stream is in fact totally dry. Humidity generators which provide greater certainty are the two temperature generator and the two pressure generator. The method is to saturate a flowing sample at specific temperatures and pressures.

During the 1960s GUM (Polish Office of Measures) built a two temperature generator for the mid to high humidity range. Soon after NIST (United States National Institute of Standards) built a two pressure generator and during the 1980s NPL (The UK national Standards Laboratory) built a two temperature standard. Later humidity standards based on two temperatures or two pressures where built at the PTB (German National Standards Laboratory), CETIAT (French Standards Laboratory) and NMIJ (Japanese Standards Laboratory).

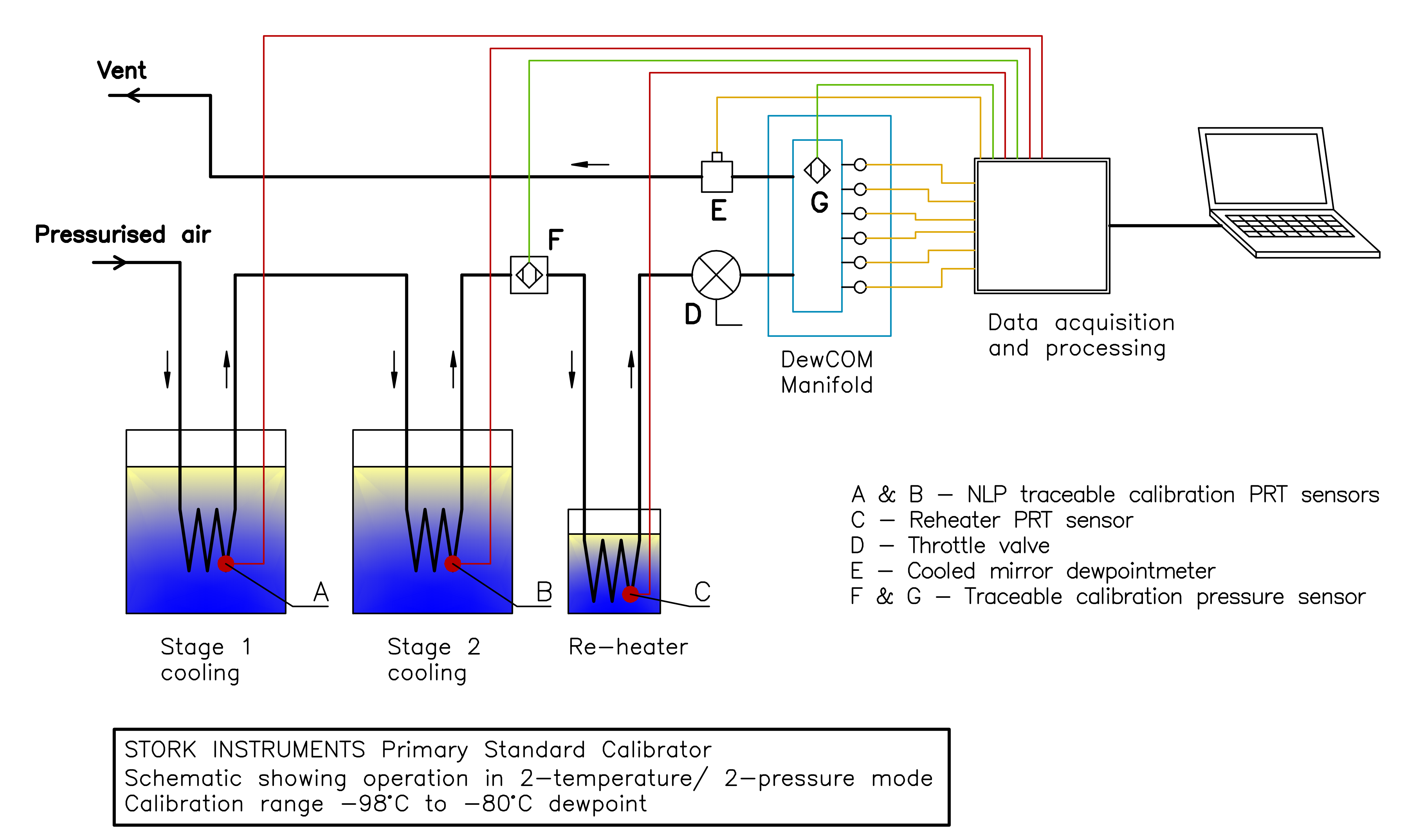

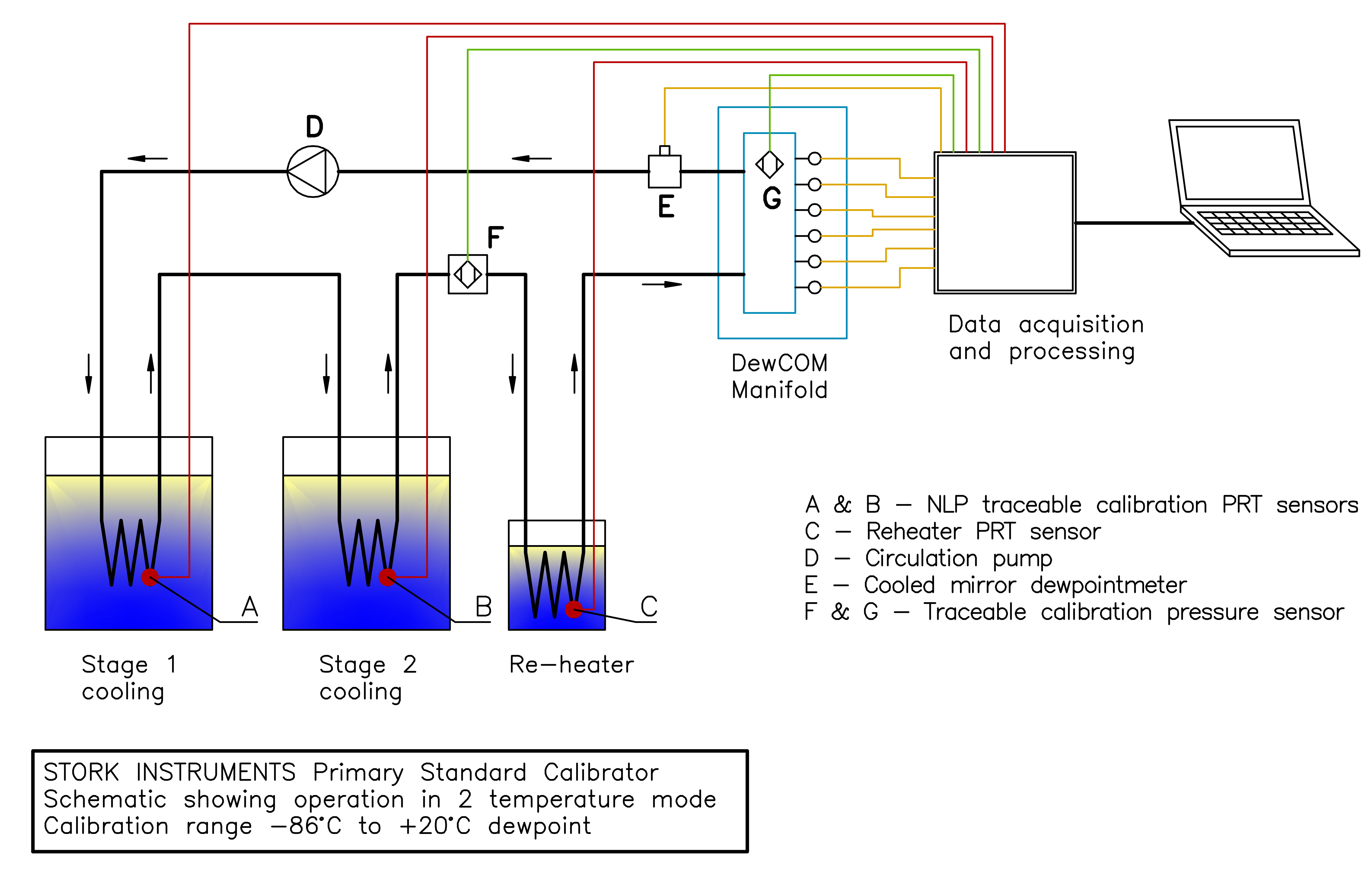

Andrew Michell, while at Michell Instruments Ltd, contributed to the development of the NPL Standard in the UK and the construction of a transfer standard for the European Bureau of Reference. Based on his experience of that work, he led the development team which designed and built the laboratory which calibrates STORK hygrometers. This laboratory uses a rig which employs a mixed flow generator monitored by a chilled mirror dewpointmeter for calibrating the company's production hygrometers. This has the capacity to automatically calibrate up to 15,000 hygrometers per year. The laboratory is additionally equipped with a two temperature / two pressure generator. This employs Lauda low temperature thermocirculators with the capability to reach -80ºC. This generator is used to regularly cross check the production generator. As a final guarantee of calibration confidence, the laboratory uses a portable chilled mirror dewpointmeter as a transfer standard between its own calibration systems and National Standards in order to provide full traceability.

The STORK Instruments In house primary standard

|

|

The Main National Standards Laboratories and their Calibration Capabilities

| National Standards Laboratory | Humidity Calibration Ranges |

| NIST (USA) | -70ºCdp to +85ºCdp / 3 to 98%rh |

| NPL (UK) | -90ºCdp to +90ºCdp / 1 to 98%rh |

| PTB (Germany) | |

| CETIAT (France) | |

| GUM (Poland) | -80ºCdp to +90ºCdp / 10 to 98%rh |

| NIMJ (Japan) | -70ºCdp to +85ºCdp |

The STORK Instruments Traceability Path

| Primary Standard | National Standards Laboratory |

| Transfer Standard | STORK-Ultra chilled mirror dewpointmeter |

| In-house primary standard |

2 temperature / 2 pressure generator Range -96°C to +20°C dewpoint |

| Production generator | Mixed flow system based on mass flow controllers |

| On line verification | STORK-Ultra chilled mirror dewpointmeter |